This guide is for LaserPost for LightBurn version 1.0.0.

Newer versions of LaserPost are now available, including an updated guide.

LaserPost is configured in multiple places, including on the machine setup, CAM setup, the individual cutting operations, and when doing the post-generation. This is accomplished using some of the advanced properties capabilities of the Autodesk CAM post-processors to provide custom properties as well as by redefining the purpose of some existing properties. For this to work, you must have (and use) a machine definition that has the LaserPost post-processor selected (do not just select the post-processor when generating or many of these options will not be available).

The following sections describe all of the options available in LaserPost in approximate order of setup and use. These screen images are from Fusion 360, though the other CAM processors (HSMWorks, Inventor) should be similar.

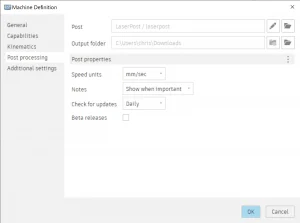

Machine Settings

LaserPost machine settings (click to enlarge).

Open the Fusion 360 Machine Library, select the nuCarve LaserPost machine and click the pencil icon (Edit Selected), and switch to the Post processing tab.

Machine settings are shared by all models, and have only a few features that rarely need adjustment:

Speed units: Selects if "mm/min" or "mm/sec" should be the unit of speed measurement. This option does not affect how LightBurn will operate on the project, as it changes only the comments and LightBurn Notes documentation.

Notes: LightBurn provides a Notes feature (visible by selecting the LightBurn File menu, and then Show Notes), and LaserPost can populate this with settings and configuration data from the various operations and configurations. By default, these are not shown unless something important warrants attention, such as an updated LaserPost version is available or problems are discovered in the LightBurn project creation. Options include "Disable" (not recommended), "Show when important" (default), "Hidden" (never shows, but remains available with File / Show Notes), and "Always" (always shows the notes when the LightBurn project is opened).

Check for updates: Sets a schedule for how often LaserPost will check for updated versions being available. Checking is only done when generating a LaserPost project. Updates are never automatically installed, and when updates are available a message will appear during a post and will also be included as "important" notes.

Beta releases: By default, update notifications only include official release versions. Enable this to also be notified of Beta and Release Candidate releases.

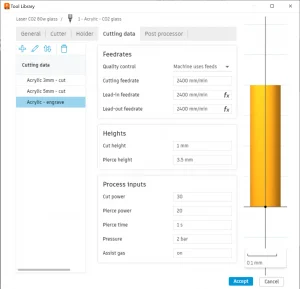

Tool Cutting Data Settings

Tool cutting data settings (click to enlarge).

Open the Fusion 360 Tool Library, select the tool library, and then select your tool. Click the pencil icon to edit, and then switch to the Cutting Data tab.

Tool cutting properties with LaserPost are used to define a material library, allowing for material-specific power, speed, and air-assist settings to be defined. Many fields are ignored, with the following fields being the ones used by LaserPost:

Cutting feedrate: This is the speed that the machine will use, in "mm/min". To use "mm/sec", simply enter the value using a formula such as "35 * 60" (35 mm per second, times 60 seconds = 2100 mm/minute).

Cut power: The power to use for the laser, expressed as a percentage (0-100%). This is the LightBurn "max" power setting.

Pierce power: This field specifies the LightBurn "min" power setting (also expressed as a percentage, 0-100%). Currently, Autodesk does not offer custom tool properties in CAM post-processor API so we override this field. It's not the most obvious but does work well.

Assist gas: Determines the default use of the LightBurn air-assist feature. This can be overridden on individual cutting operations (see below). Recommended values are "on" for enabling air-assist, and "off" for disabling (though any value can be used, where "off" or "none" will disable air-assist and otherwise it will be enabled).

CAM Setup Job Settings

Fusion 360 CAM Setup (click to enlarge).

Select the job setup in the CAM browser tree, right-mouse click, and select "Edit".

Each model must have one (or more) CAM setups that contain cutting operations. There are no custom LaserPost properties on this window, but the following setup details are important for the successful use of LaserPost:

Machine: You must set up a machine that is configured to use the LaserPost post-processor, and the setup must select that machine. If this is skipped, custom properties in the 2D Profile Cutting Operation will not be available.

WCS Orientation: Your setup must use the same orientation as your laser cutter/engraver, and also the same as your LightBurn machine origin. There are multiple ways to do this, and one approach is to use "Select X & Y axis" and then select a horizontal line for the X axis and a vertical line for the Y axis.

WCS Stock point: The stock point must be the same as the origin as used in LightBurn, otherwise the model may be reversed, rotated, or otherwise incorrectly positioned. Select the corner (usually bottom-left or top-right), and check the "Flip X Axis" and/or "Flip Y Axis" to get the X and Y lines pointing in the direction of the stock/model.

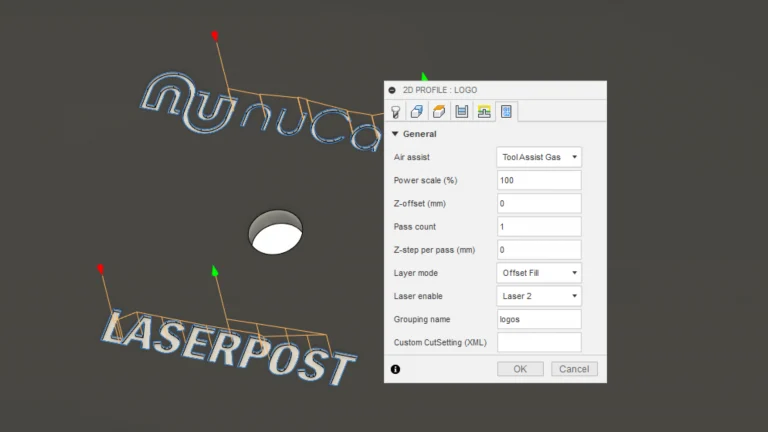

2D Profile Cutting Operation Settings

All LightBurn shapes are defined using the "2D Profile" cutting operations (including for cutting and engraving tasks) where you select the geometry of your model. While you can have a single operation for large jobs (that share the same settings), it is recommended to use multiple, smaller operations (such as one to cut inside shapes, and another for an outside cut). This makes managing and understanding the operations easier, and results in more usable LightBurn groups.

The following three tabs are important to set up correctly.

2D Profile cutting operation (click to enlarge).

On any 2D Profile cutting operation, right-mouse click, select "Edit" and click the "Post Properties" tab.

The first tab is the Tool setting tab, where you select the tool (the base material), and set the cutting mode and preset that define how the operation will cut or engrave the material.

Tool: Select the tool from your Tool Library for the material type you are cutting. This will populate the "Preset" field to contain the various material settings available in your library.

Cutting Mode: This defines how the CAM system will generate the paths for the cutting operation. The "Through - auto" option is often used for cutting through the material and includes lead-in and lead-out operations (which energize the laser in scrap areas of the stock and move into the material to reduce scorching at high power). The "Etch" option should be used when doing etching, such as text and logos, and will energize the laser on the geometry (with no lead-in or lead-out). These options adjust the generated shape and do not affect the laser power or speed.

Preset: Selects the specific material settings from your tool / material library. This is where the laser settings such as power, speed, and air assist get defined.

Cutting Feedrate (optional): When you select a preset, the material (tool) library feedrate speed setting will be transferred to this field. You can further tune this value for this specific operation if desired.

2D Profile cutting operation (click to enlarge).

On any 2D Profile cutting operation, right-mouse click, select "Edit" and click the "Post Properties" tab.

The Geometry tab is where you select the parts of your solid model (or sketch) you want to include in this operation. There are no LaserPost-specific settings.

2D Profile cutting operation (click to enlarge).

On any 2D Profile cutting operation, right-mouse click, select "Edit" and click the "Post Properties" tab.

The post-properties tab on the 2D Profile cutting operation allows you to precisely configure the LightBurn layer options. If this tab is not showing up, make sure your CAM setup (see above) has selected a machine that is configured to use the LaserPost post-processor.

Air assist: Determines if air assist will be used. The default, "Tool Assist Gas", will use whatever setting has been defined with the Preset (Tool Library Cut Settings). You can also disable air ("Off") or enable air ("On") for this operation.

Power scale (%): Sets the LightBurn "Power scale" to adjust the laser power.

Z-offset (mm): Sets the LightBurn "Z-offset" layer property.

Pass count: Sets the LightBurn "Pass count" layer property.

Z-step per pass (mm): Sets the LightBurn "Z-step per pass" property.

Layer mode: Sets the LightBurn layer mode. Defaults to "Line", and can be set to "Fill" or "Offset Fill". When a fill mode is used, it is recommended to use the "Etch" cutting mode (on the Tool tab). LaserPost will automatically remove non-connected shapes (such as lead-in and lead-out) to ensure only valid fillable shapes are generated when a fill mode is used (these shapes are still generated but commented out in the LightBurn project file).

Laser enable: Sets the LightBurn laser enable property. Options include "Disable output", "Laser 1" (default), "Laser 2", and "Both".

Grouping name: For more precise control over the grouping of shapes in operations, this field can be given a name (such as "Logos"). All operations that share the same name will be automatically grouped (with their operation as a sub-group, unless disabled in post-property generation).

Custom CutSetting (XML): There are many options and features for setting layer properties in LightBurn, and including them all in LaserPost would make for a difficult-to-use experience. If you wish to use the more advanced features, such as using sub-layers, go to LightBurn and create the layer and save the project using the "LBRN (Legacy)" format. Open the project in a text editor and find the "<CutSettings>" for that layer, and copy the entire XML (including the "<CutSettings>" through "</CutSettings>") and paste that XML here. All other layer settings will be ignored when this option is used.

Post-processor Generate Settings

LaserPost post-processor actions (click to enlarge).

On the Actions menu bar, select Generate to start the post-processor.

Several options are available when generating a LightBurn project (when Generate Post runs the LaserPost post-processor). Autodesk does not save these settings with the project, so be careful to set them correctly when changing models.

LightBurn file settings:

Comments: LaserPost injects helpful comments into the LightBurn project file. These comments do not affect the operation of the project but can be useful when looking at the project's XML. Options include "Disable", "Normal" (default), "Detailed" (includes extra settings information), Debug (useful when trying to understand how LaserPost is working), Insane (rarely needed but occasionally needed to debug LaserPost issues).

Group operations: This checkbox, default on, tells LaserPost to create a LightBurn group around each individual operation, making it easier to select and manage from LightBurn.

Group shapes: This checkbox, default on, tells LaserPost that shapes found within a single operation should be grouped. If the operation contains only one shape, no group will be created even when this is enabled.

Power overrides:

Etch power (min and max, %): Optionally override the power level of all "Etch" cutting mode operations.

Vaporize power (min and max, %): Optionally override the power level of all "Vaporize" cutting mode operations.

Through power (min and max, %): Optionally override the power level of all "Through" cutting mode operations.

Workspace:

Trace stock: When enabled (default), includes a layer and shape that outlines the edges of the stock in the LightBurn project. This layer will have its output turned off so it does not energize the laser, but is useful for seeing the stock outline inside LightBurn. Unselect the checkbox to disable this feature.

Offset X axis: Offsets all X positions in the LightBurn project by the specified number of millimeters. Similar to using the setup Stock Offset feature, but operates on all setups in the project.

Offset Y axis: Offsets all Y positions in the LightBurn project by the specified number of millimeters. Similar to using the setup Stock Offset feature, but operations on all setups in the project.

Help us improve LaserPost

Hopefully, this has been helpful to get the most out of LaserPost. If you find anything inaccurate or missing, wish we would add a feature, or find a bug, please let us know by opening an issue on GitHub or sending us a message. And please consider sharing LaserPost with your friends and colleagues or more broadly with videos and articles on social media.